Wheels

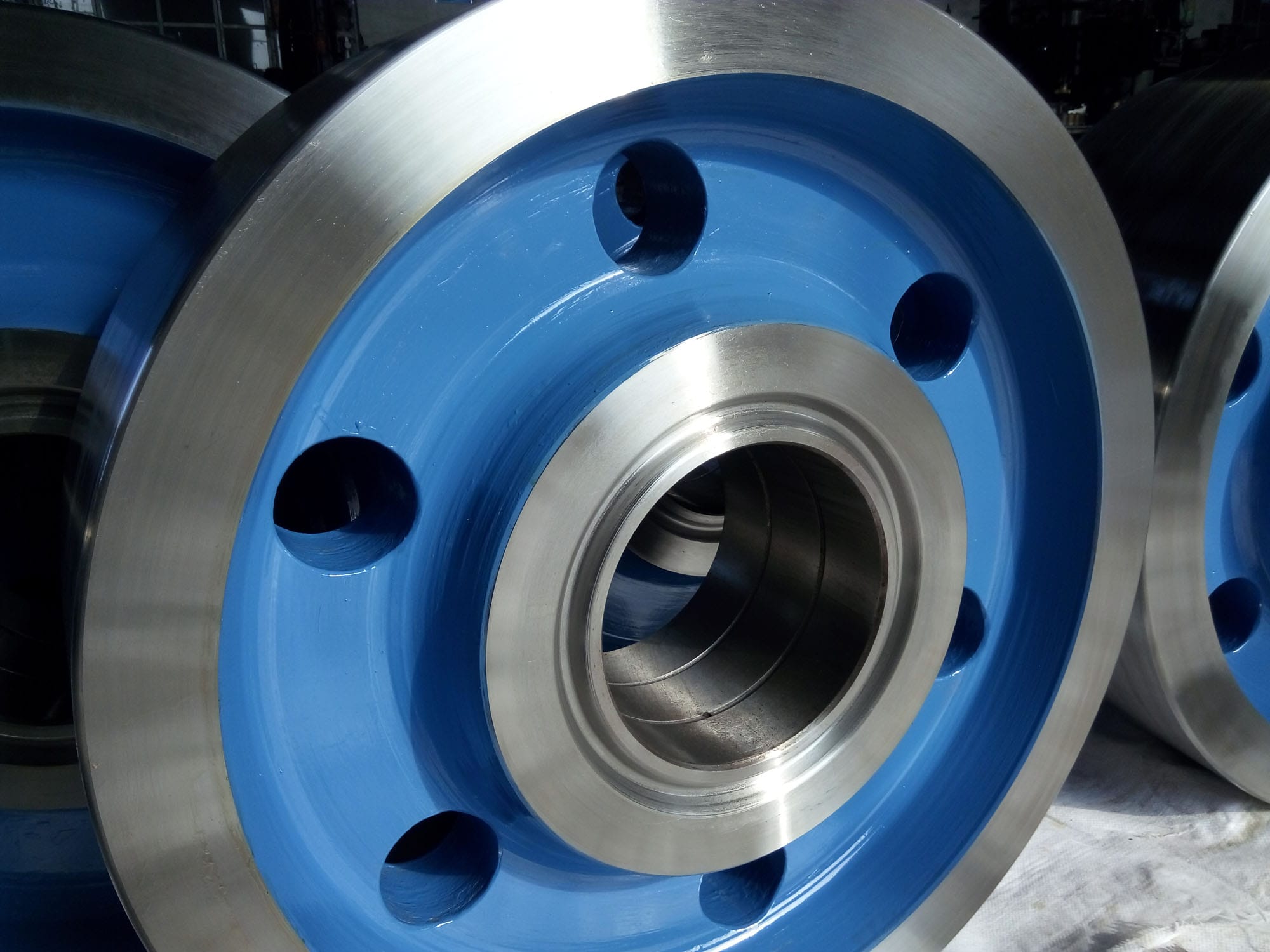

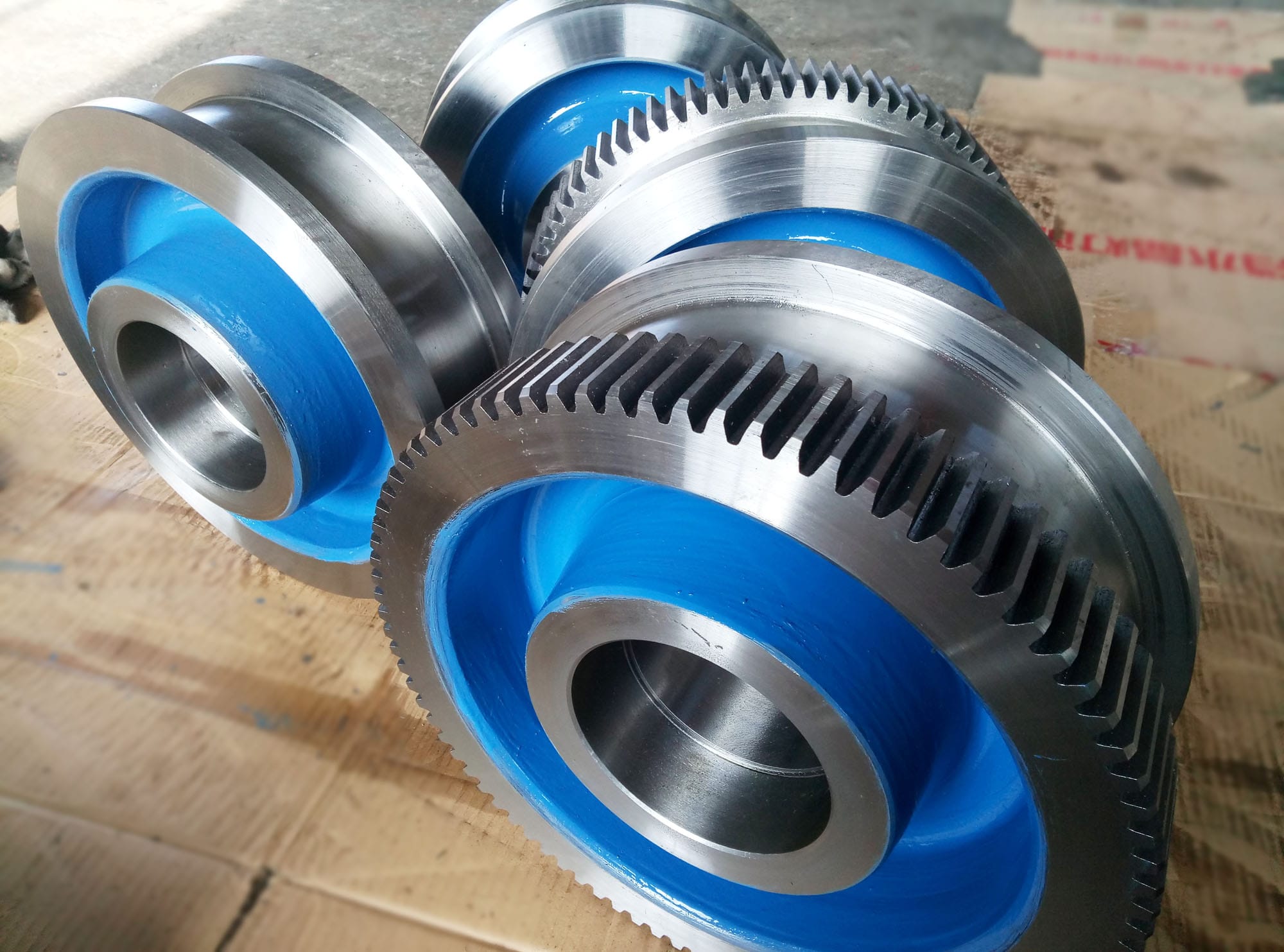

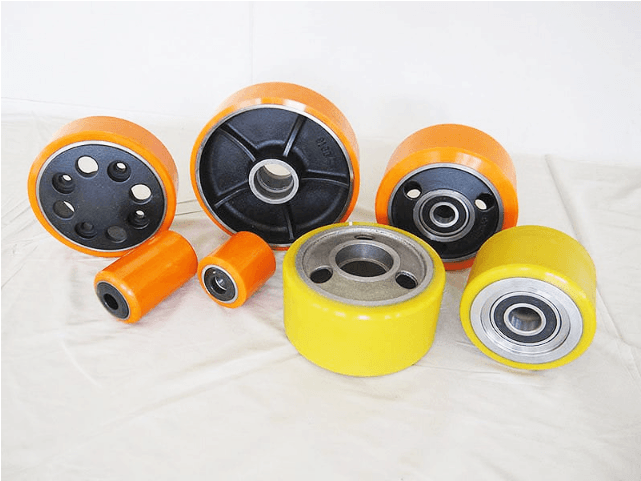

Our wheels are mainly used in all kinds of lift machines, such as single girder overhead crane, double girder overhead crane, gantry crane, port crane and transfer cart etc. FLANGED CRANE WHEELS are various, like single rim wheel, double rim wheel, non-rim wheel, and other nonstandard wheels.

DOUBLE FLANGED CRANE WHEELS worked on rail of the Equipment. To load equipment and goods weight. Double Flanged can prevent the wheels break away from the rails. SINGLE FLANGED CRANE WHEELS has the same effect with Double Flanged crane wheels. Single flanged crane wheels usually used in the trolley and transfer cart.NON FLANGED CRANE WHEELS used for a variety of equipment. Wheel tread contact with the rails. In order to keep the Non Flanged crane wheels never break away from the rails, need to assemble level of the wheel on the equipment to keep Non Flanged crane wheels vertical traveling with the rails. Avoid wheels contact with rails side, prevent rail gnawing.

According to the forming method,the wheels have forging and casting two types of wheels. The material of forging wheels includes 42CrMo4, AISI4140, 41Cr4, A504, SSW-Q1R, 65Mn,1045,1055,1060,1070,These material can also make casting wheel according to the customer's demand. At the same time, we can also make cast iron wheels. According to the material can be divided into Grey Cast iron wheels and Ductile iron wheels,Grey cast iron wheels include HT200,HT250,HT300,and ductile iron wheels include 400, 500,600,700 etc.

Flanged crane wheels are available in a wide range of standard sizes. In addition, Flanged crane wheels to meet your special design requirements can be produced in virtually any size, configuration and surface finish condition. Flanged crane wheels are available in any surface hardness up to 55 HRC including our standard heat treatments.Flanged crane wheels are also able to be Deep Hardened or Differentially Hardened for heavy wear or load requirements. For applications with severe flange loading we also manufacture an AISI-4140 "Super Tough" crane wheel.For example for ZPMC port crane wheel.

Different stages of hardness was listed,Untreated, Annealed, Normalized Crane Wheels:

- Rim Toughened 32-41 HRC,300-380HB

- Deep Hardened Crane Wheels Up to 55 HRC

- Super Tough AISI-4140 Heat Treated up to 500 BHN

Key words: crane wheel, overhead crane wheels, gantry crane wheels, port crane wheels, transfer cart wheels, wire rope sheave, PU wheels

Send Us a Message.

Complete the form below, Or email to sales@dgcranewheel.com. Someone from our sales team will get back to you within 24 hours!